===

When it comes to repairing your Liebherr equipment, having access to the right information and resources is crucial. That’s where the comprehensive factory manual from Liebherr comes in. This authentic manual is a treasure trove of knowledge that contains everything you need to effectively repair and maintain your Liebherr machinery. In this article, we will explore the benefits and features of this invaluable resource, and how it can assist you in unlocking the secrets to efficient Liebherr repairs.

The Comprehensive Factory Manual from Liebherr

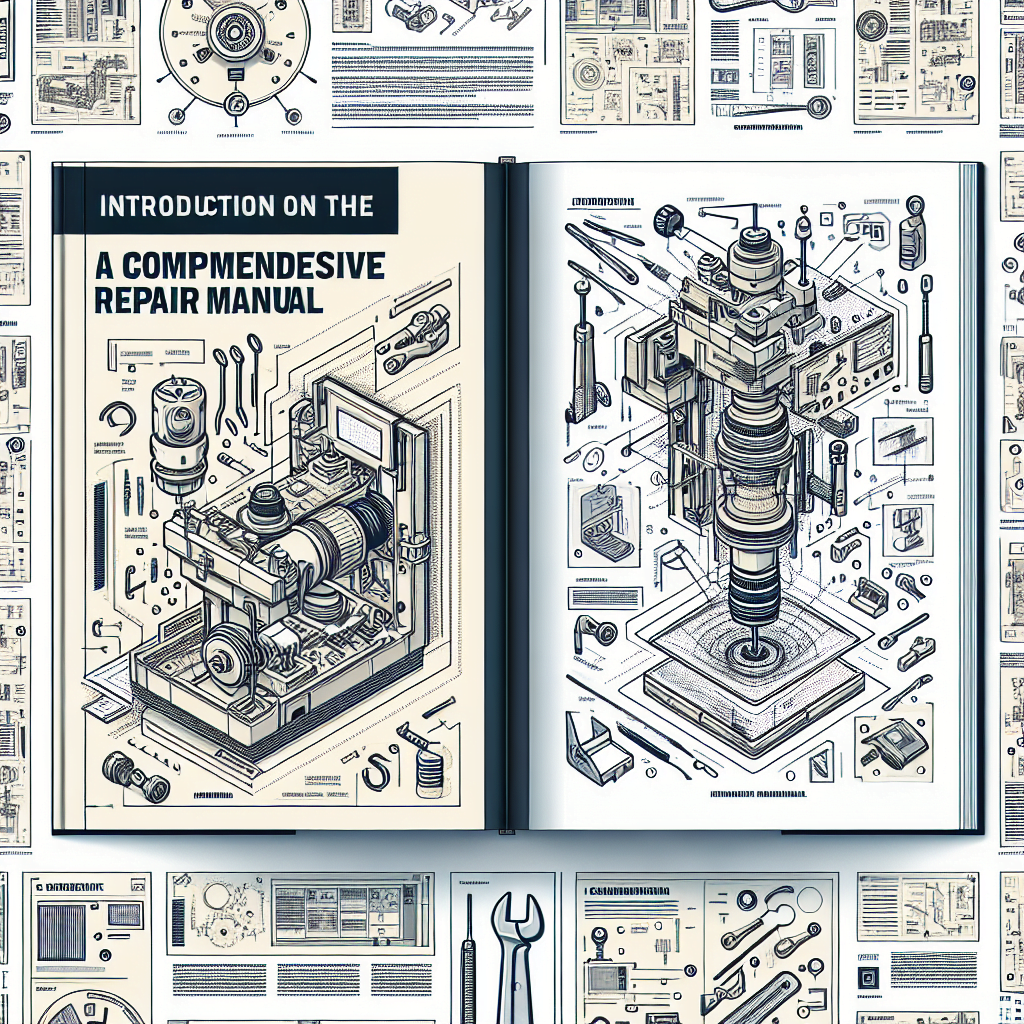

The factory manual from Liebherr is the ultimate guide for anyone looking to repair their Liebherr equipment. It is a comprehensive resource that covers all aspects of maintenance and repair, providing detailed instructions and diagrams. Whether you are a professional technician or a do-it-yourself enthusiast, this manual is designed to meet your needs. It contains information on troubleshooting, servicing, and repairing various Liebherr models, ensuring that you have all the necessary information at your fingertips.

Your All-In-One Guide for Repairing Your Liebherr

No matter the issue you are facing with your Liebherr equipment, the factory manual has got you covered. From electrical systems to hydraulic components, this manual provides step-by-step instructions on how to diagnose and repair problems. It includes detailed diagrams and illustrations, making it easy to understand and follow. Furthermore, it also provides information on the recommended tools and equipment needed for each repair, ensuring that you have everything you need to get the job done right.

Unlocking the Secrets to Efficient Liebherr Repairs

Efficiency is key when it comes to repairs, and the factory manual from Liebherr helps you achieve just that. By following the instructions and guidelines provided in the manual, you can save time and effort by avoiding unnecessary steps or mistakes. The manual also includes valuable tips and tricks that can help you streamline the repair process and improve your overall efficiency. With this manual in hand, you can confidently tackle any repair task and ensure that your Liebherr equipment is up and running in no time.

A Treasure Trove of Knowledge for Your Liebherr Maintenance

Maintenance is an essential aspect of ensuring the longevity and optimal performance of your Liebherr equipment. The factory manual from Liebherr not only covers repairs but also provides detailed information on routine maintenance tasks. From regular inspections to preventive maintenance schedules, this manual offers a wealth of knowledge to help you keep your Liebherr machinery in top condition. By following the recommended maintenance procedures outlined in the manual, you can minimize downtime and maximize the lifespan of your equipment.

Conclusion

The factory manual from Liebherr is an indispensable resource for anyone owning or working with Liebherr equipment. Its comprehensive nature, detailed instructions, and valuable insights make it the ultimate guide for efficient repairs and maintenance. By utilizing this manual, you can save time, effort, and money by effectively addressing any issues that may arise with your Liebherr machinery. So, if you’re looking for a reliable and comprehensive resource to assist you in repairing and maintaining your Liebherr equipment, look no further than the authentic factory manual from Liebherr.

===

For more information and to access the comprehensive factory manual from Liebherr, visit liebherr-manual.com.